Week 2

Lets play with machines

Vinyl Cutter

Roland Camm -1 Installation

First time setup (software force control in fab modules)

Go to http://localhost:631/ in browser

Using C Unix Printing System (CUPS 1.7.2) create a new profile for the vinyl cutter. Name should be "vinyl"

and it is case sensitive

Vinyl sheet loaded properly in the vinyl cutter.Fix the vinyl sheet between the white marked area clse to left side of the vinyl cutter machine

Cover the Sensor

Align the material

Set Orgin : position the origin using right,left,up and down key. Once its done press and hold the origin button

(3 seconds)

The test cut

Adjusting Force/Adjusting blade length

Remove the circle without removing the square

Make: RAW

Model: RAW

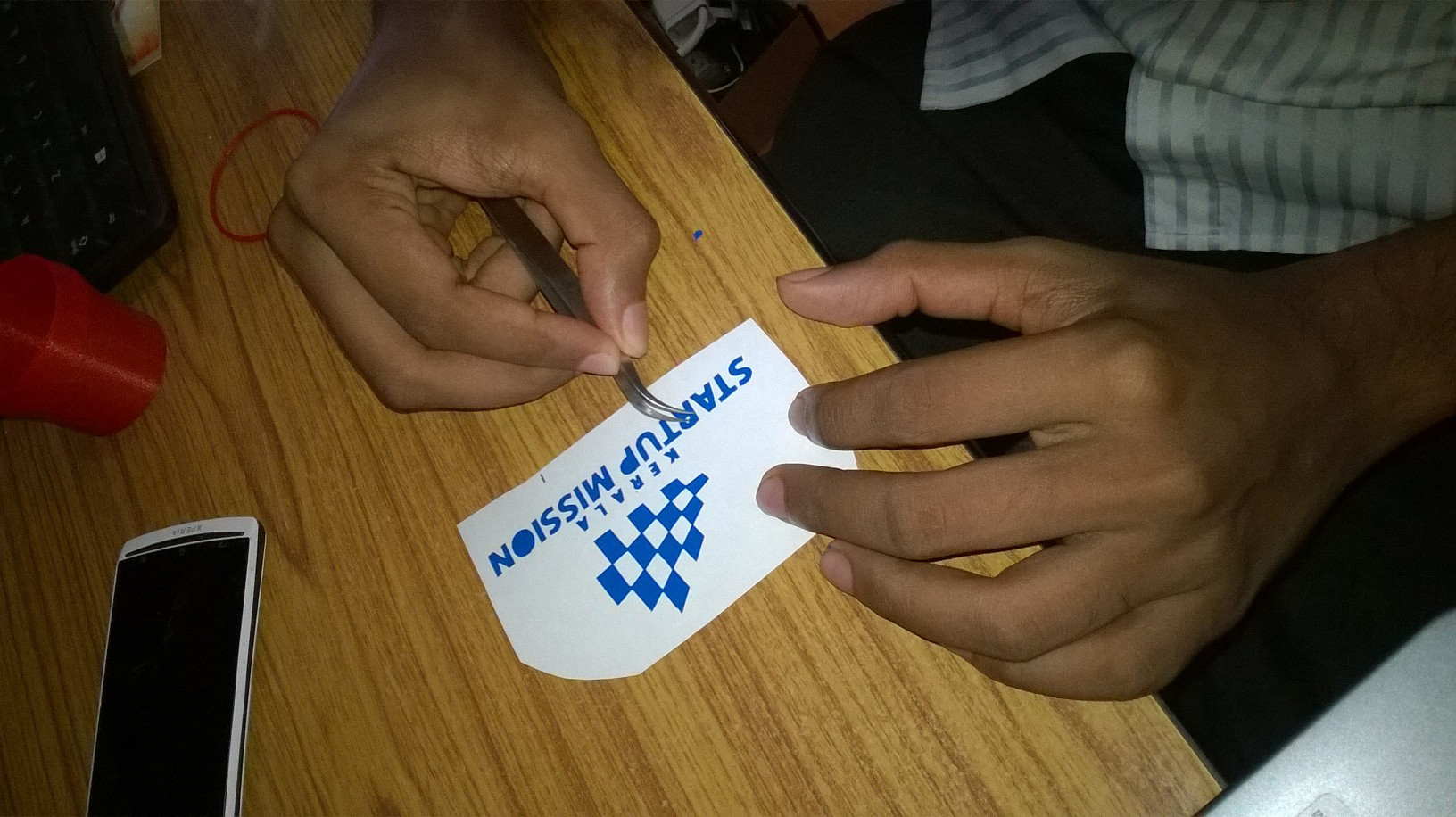

Startup mission Logo downloaded from web.

open fab module

input format : png

Output process: Ronald Vinyl cutter

File

Startupmission.png

Startupmission.png

Material Used :

Vinyl

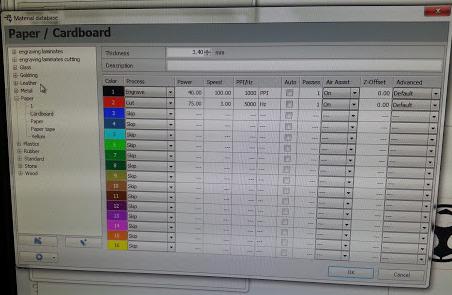

Laser Cutter

Install Laser printer software.

Design in Inkscape and then the saved .svg file is given as input to the Laser cutter.

laser cutter cuts/engraves by burning the material

Focus the lens by adjusting the material surface.

Effects of unfocused lenses

Kerf. Importance in design

Jobs

Vector cutting

Vector engraving

Raster engraving

Settings

Speed

Power

Frecuency

Security

Danger of a Laser Class 4 beam

Machine has built in protection

Do not try to mess or hack the lid. It's not cool

Fire

NEVER leave a laser cutter unattended. EVER

If you ever see an unattended laser machine working: SHUT IT DOWN

Check your design against double lines

Check your design against heat concentration (can the material handle it?)

Not laserable products:

Vinyl

PVC

Any unknown material

Laserable things

Anything specifically made to be laserable

Acrylic

Cardboard

Wood

Natural fibers and leather

In general, all Natural materials

Laserable things that are not recommended

The risk of Long term exposure to chemicals

MDF

Anything laserable that you think it might contain traces of nasty things (glues, paints, coatings…)

Files

spintop.svg

spintop.svg

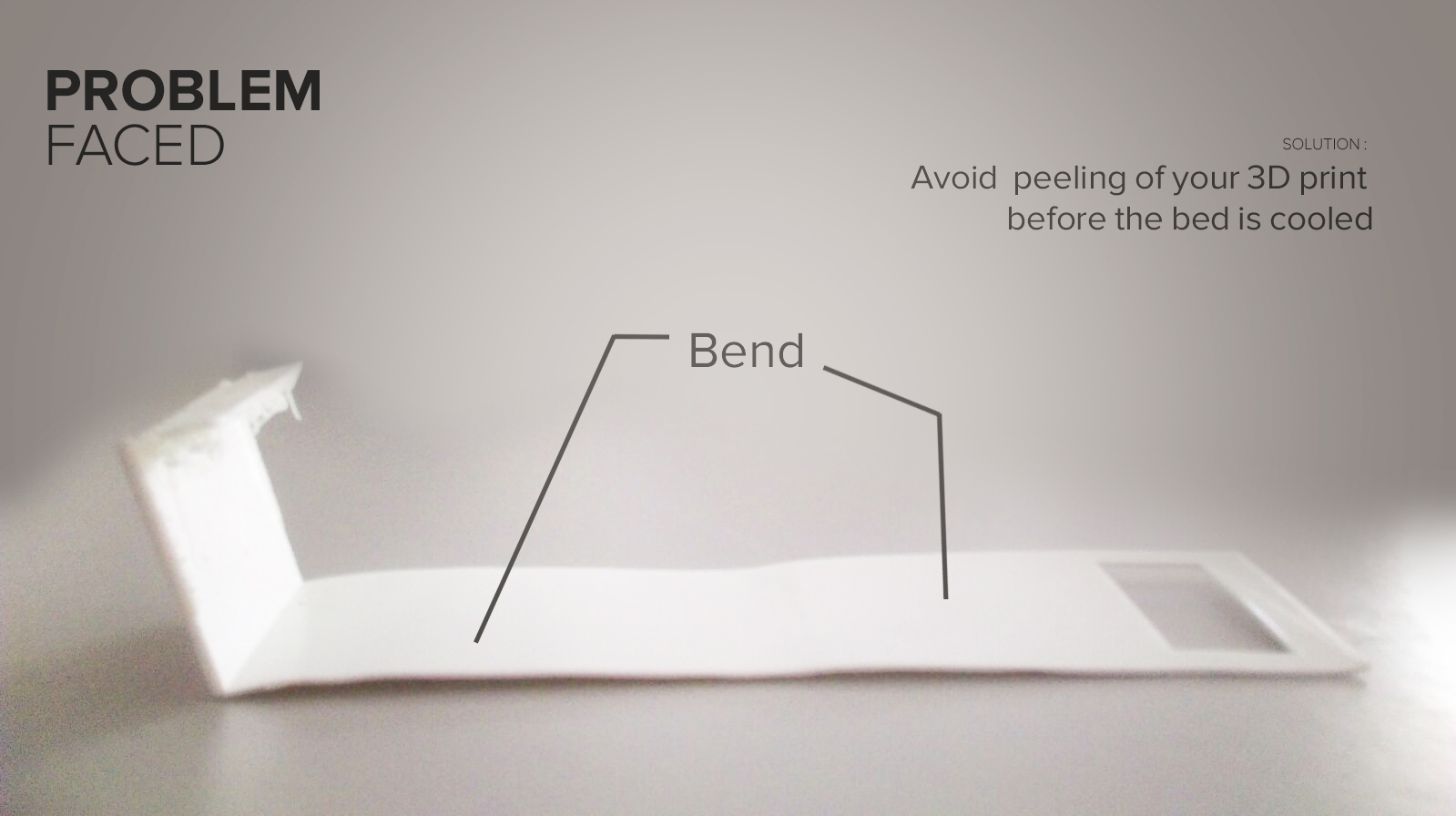

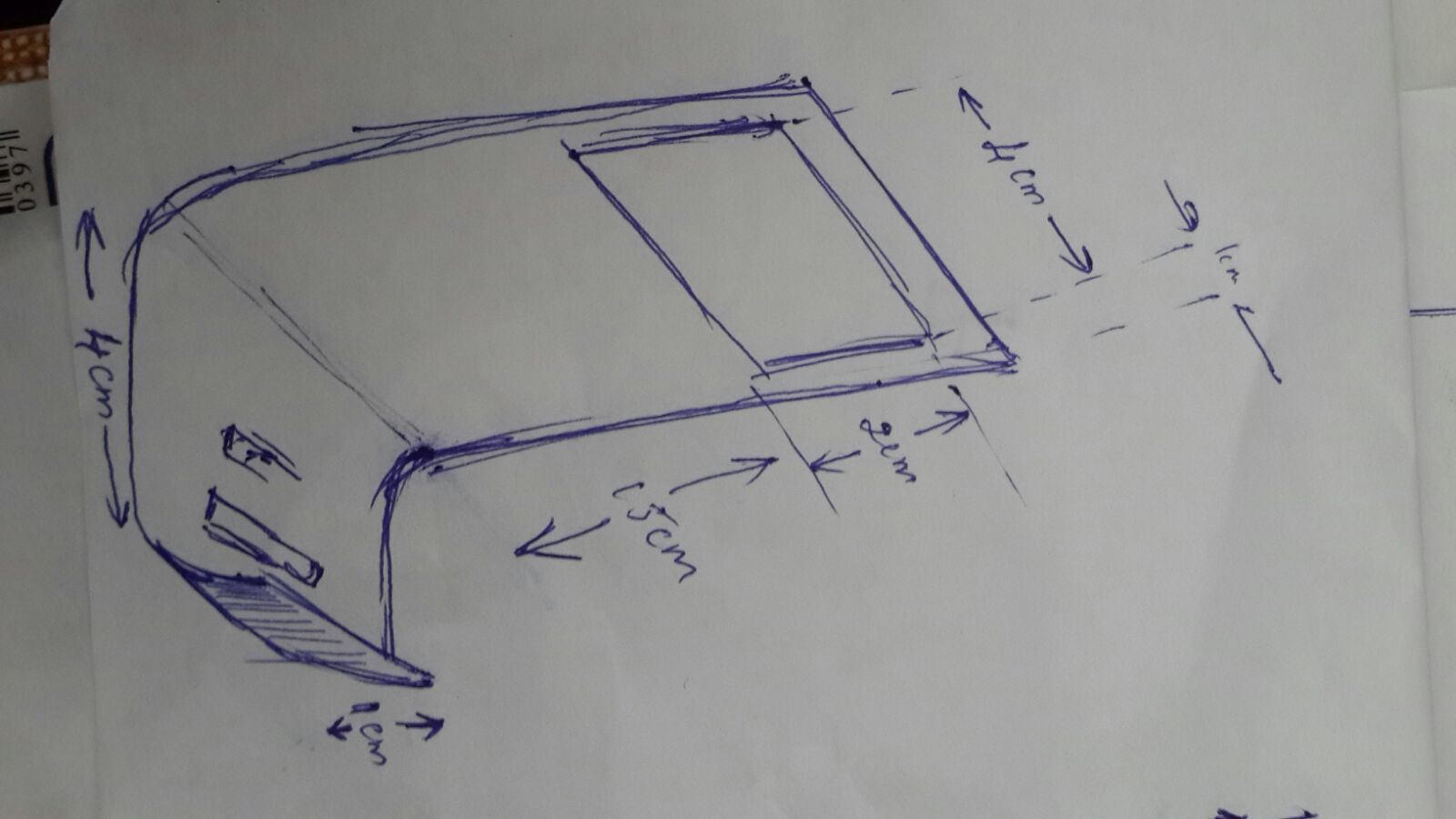

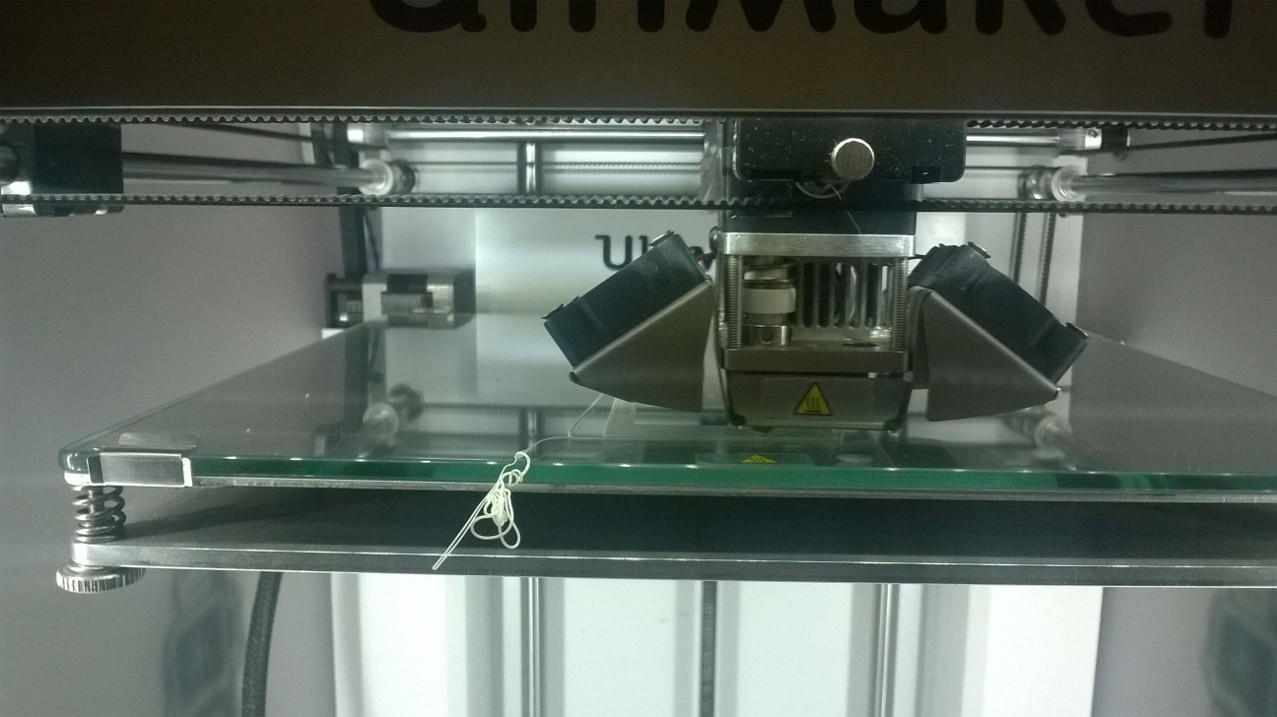

3D Printer

Ultimaker 2

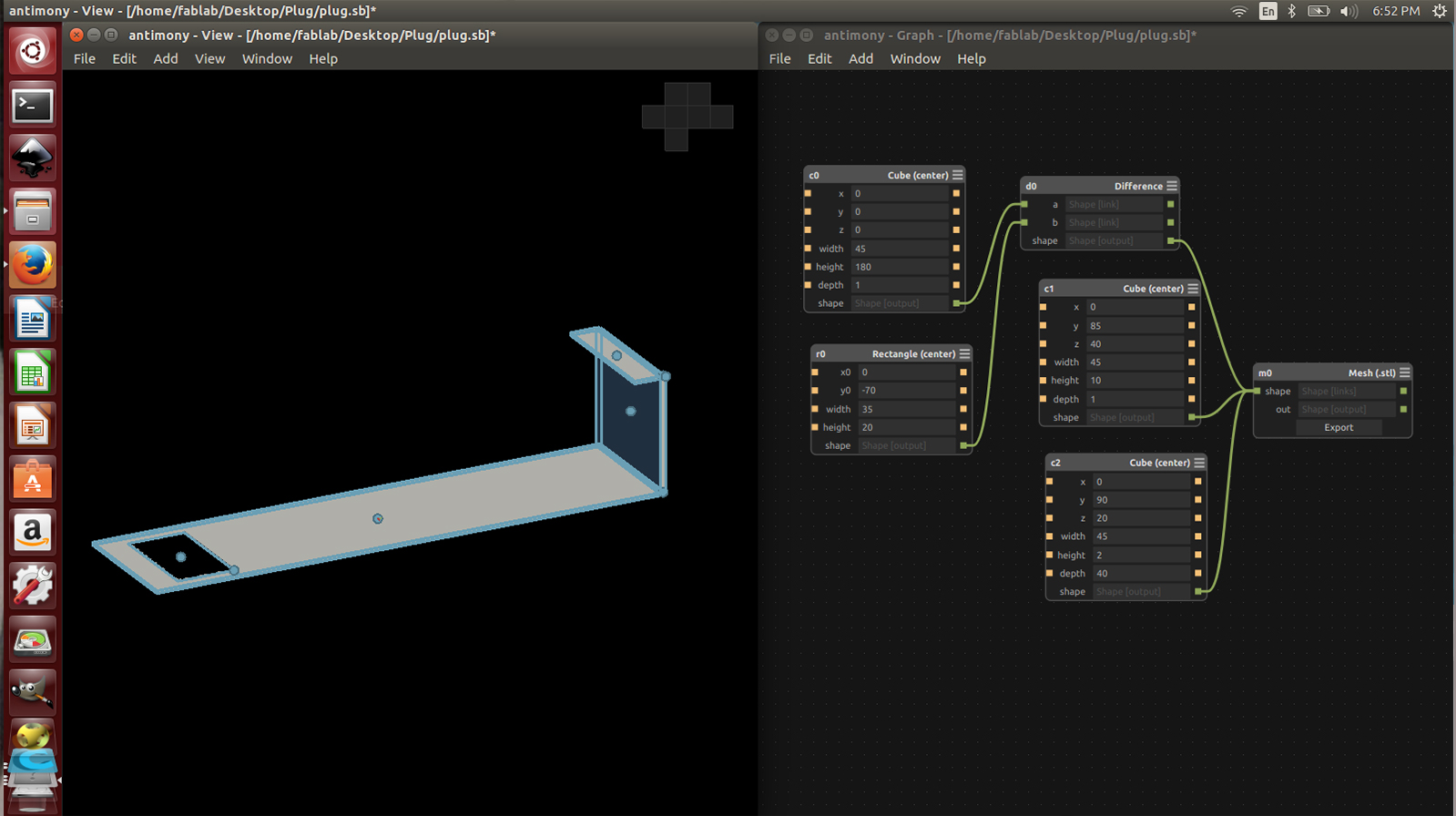

Design in antimony

Export .stl

open in cura & convert to G code

Copy the Gcode to SD card and print

Files

phoneholder.sb

phoneholder.sb

phoneholder.stl

phoneholder.stl

phoneholder.gcode

phoneholder.gcode

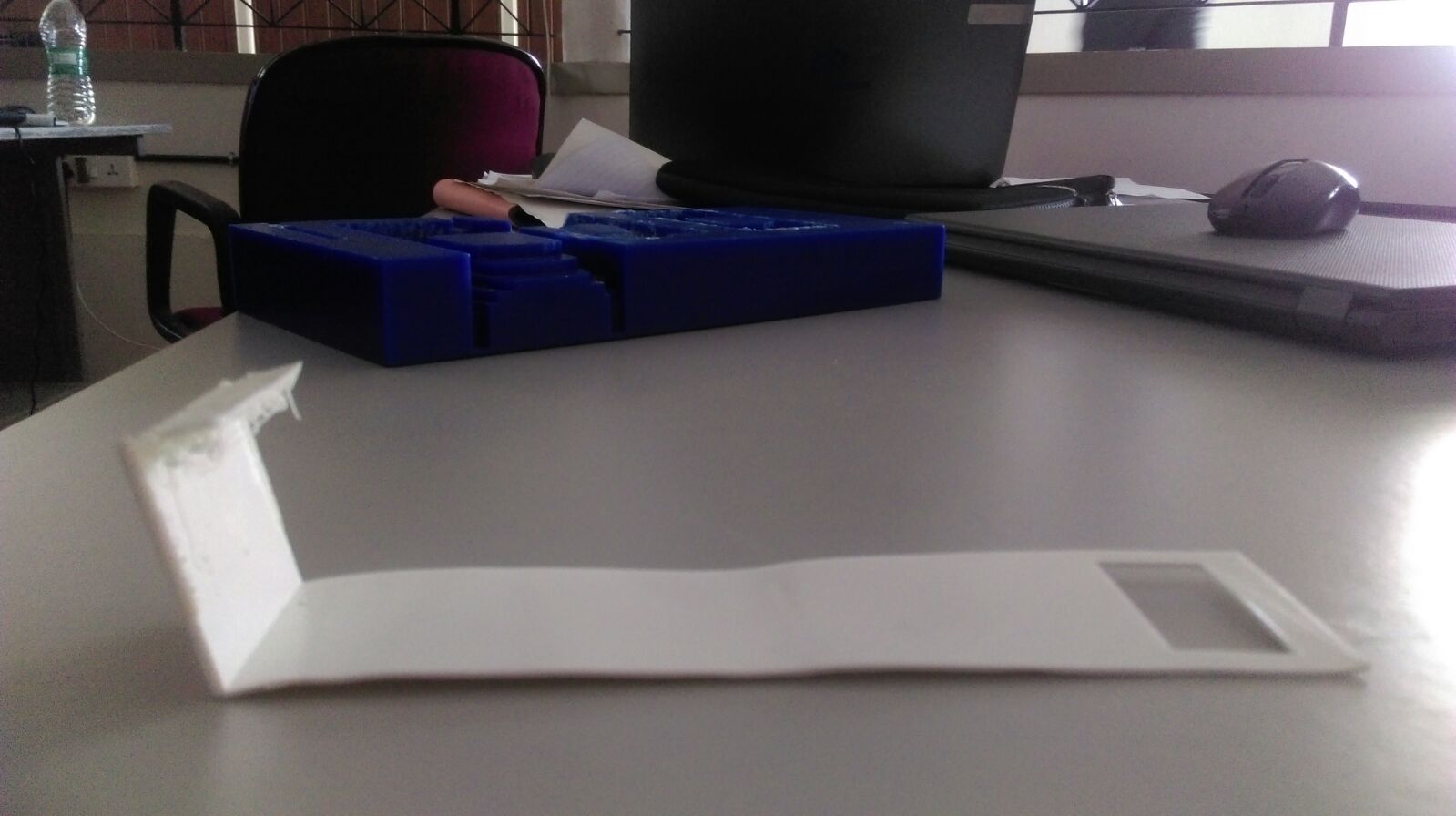

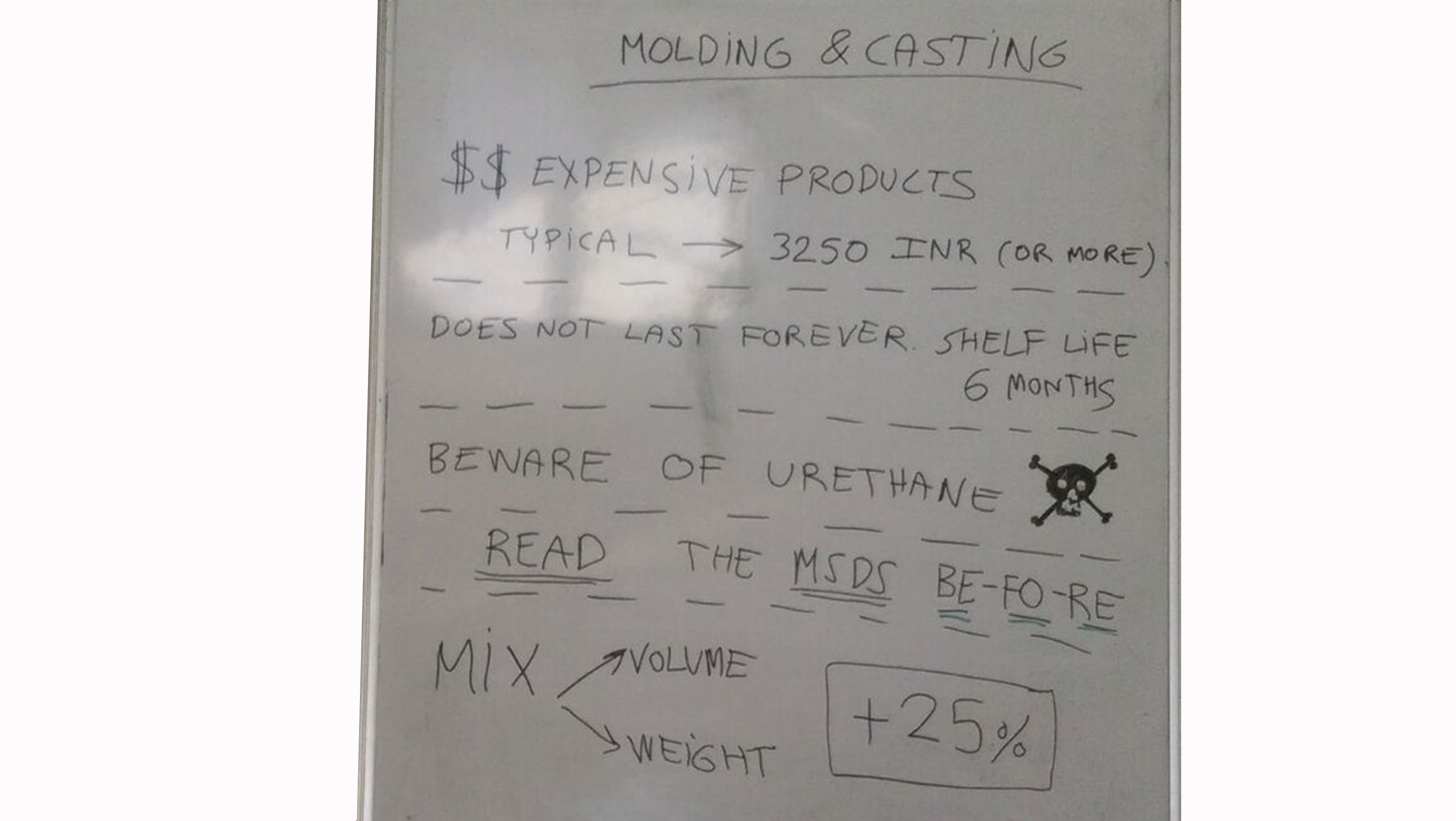

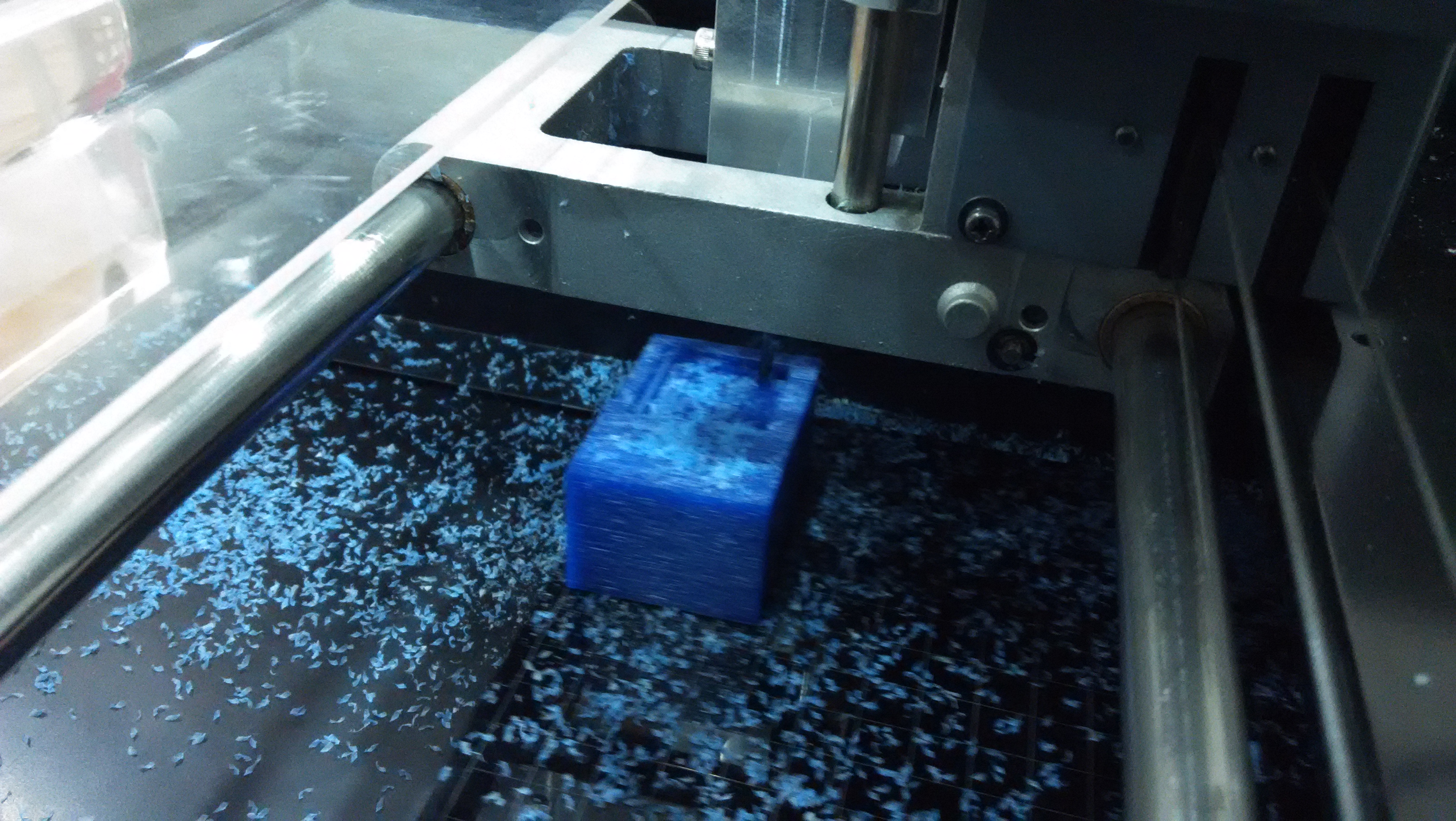

Molding and Casting

Designing sigle sided mold in antimony

Forward design (start with the castable object) vs backwards design (start with the wax you have)

Silicon clearance

Wax clearance

Advantages of antimony

DESIGN FOR the tool you have or BUY A TOOL for the job you want to mill

Inner corner limitation and design workaround

Tool depth limitation

Clearance parameter in fab modules (compiled version only)

Roland Modela

Mixing Pay attention. By volume not necessarily equal to by weight!!!

Remember. Expensive material. Calculate silicon volume or weight and allow 25% extra

Files

hook.sb

hook.sb

hook.stl

hook.stl

hook.png

hook.png

Shopbot

Shopbot

Join lines into polylinesNesting your design

Toolpaths in Partworks (Vectric) software

Drill toolpath

Pocket toolpath

Cutout toolpath

Always interior cutouts firsts

Use tabs or drill holes to fix your parts

Beware: Interior, exterior or on the path