Week 3

Electronics & Programming

Day 1: FabISP

Programmer

Proper use of the heat gun. Remember to put it in cold air after use until no heat comes out.

Soldering SMD components

It’s not like painting. Doesn’t work like this. Soldering Iron in, Solder in, Solder out, Soldering Iron out.

Use the double side tape to fix the board to the table

Start with the microcontroller, continue towards the perimeter

Easy with the tweezers

Soldering day - No coffee

Use good lighting and loupes

In groups of 2 people, Fabricate the Fab ISP

Prepare the Roland Modela bed and sacrificial layer

Download from Fab Academy Electronics production week or follow http://fabacademy.org/archives/2015/doc/electronics_production_FabISP.html

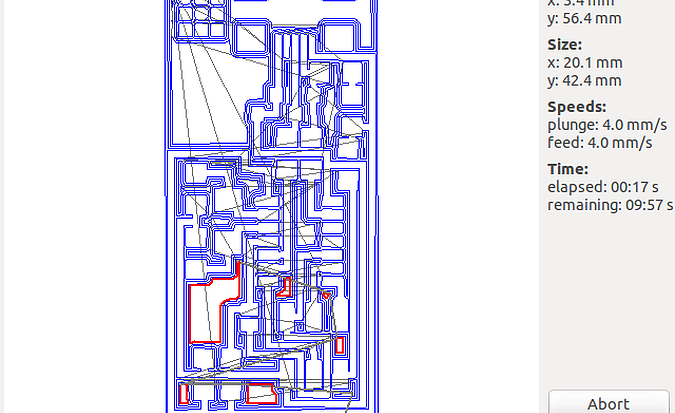

Mill traces, cut board

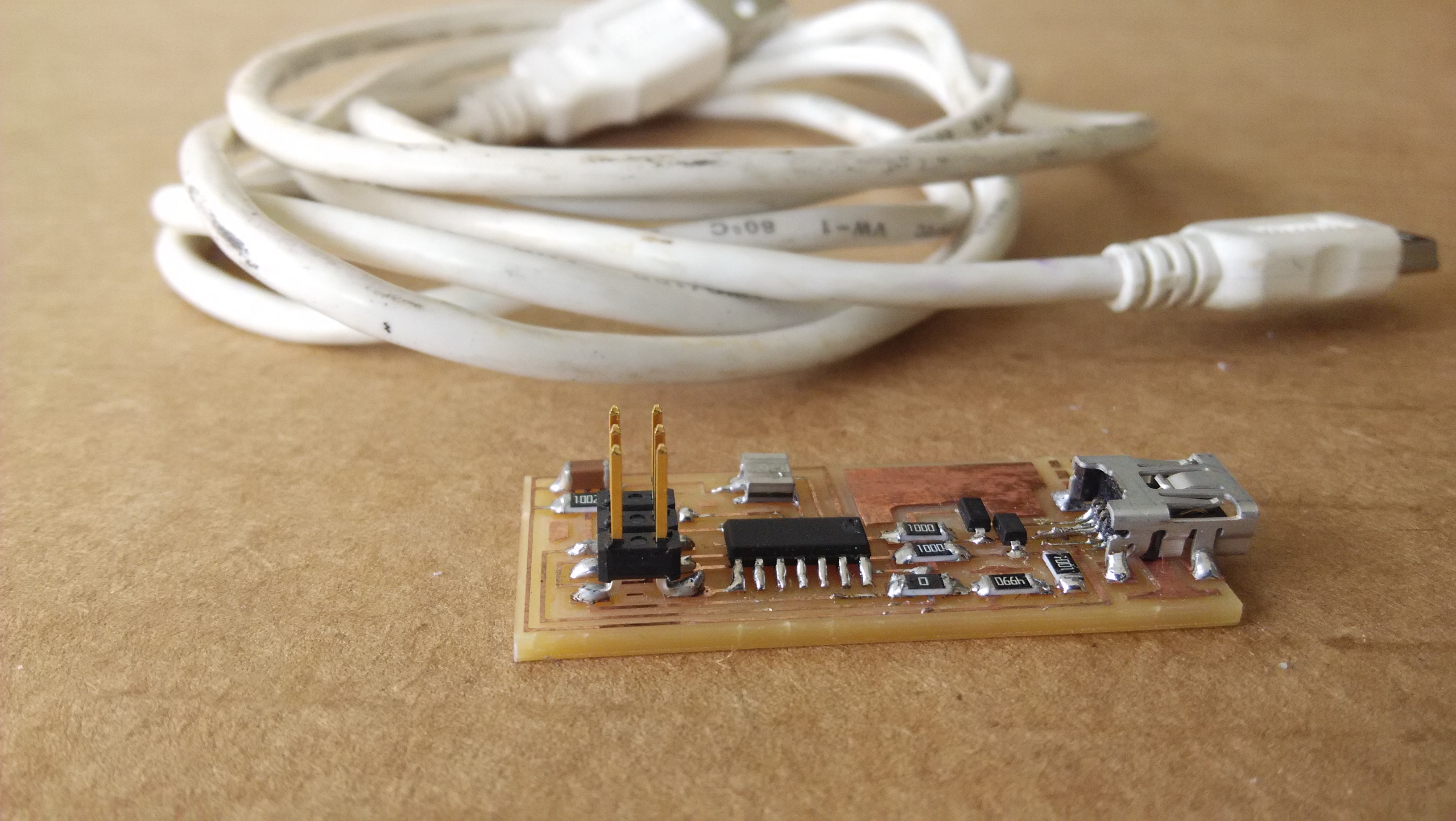

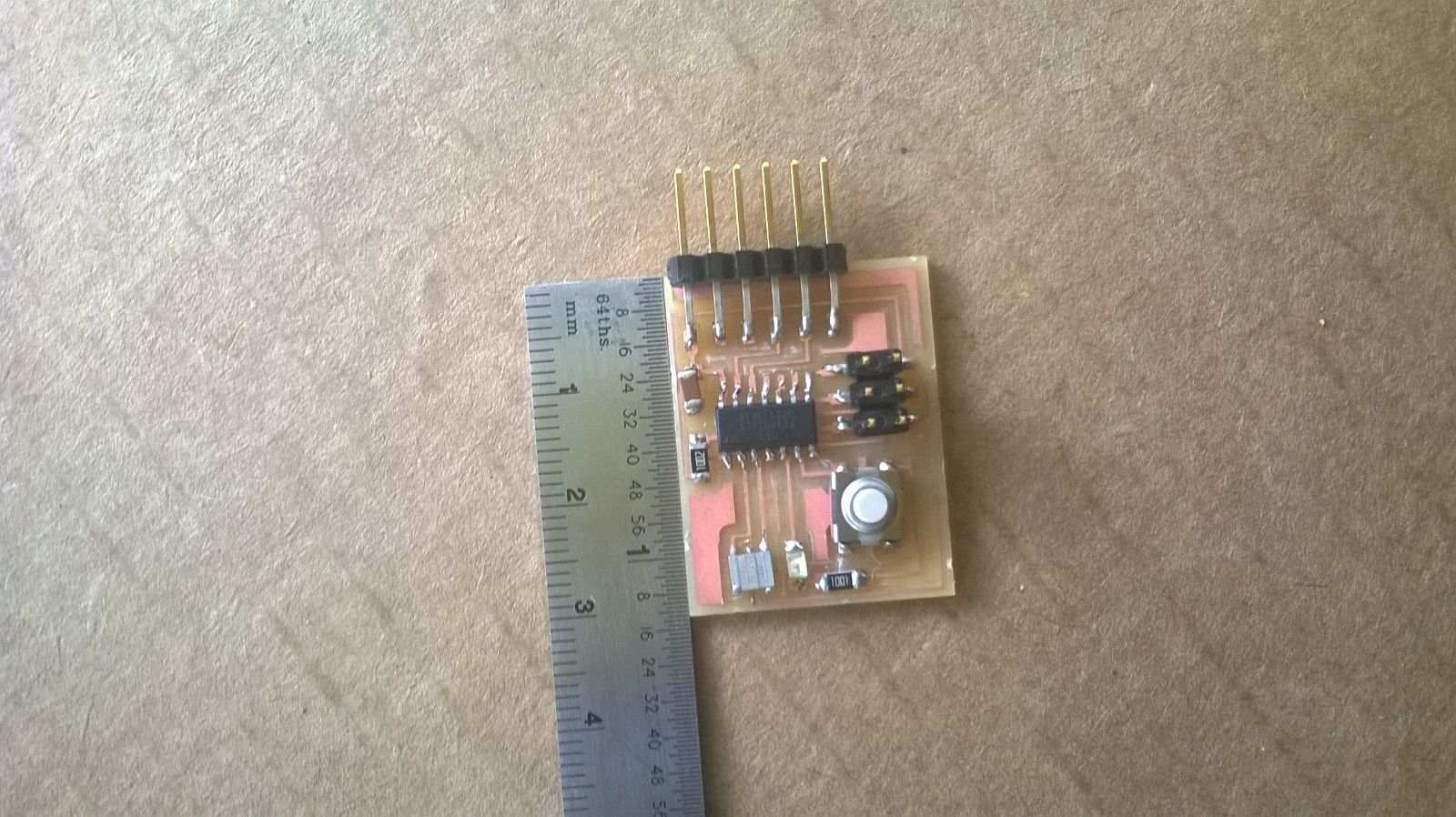

Stuff

Program and Debug http://fabacademy.org/archives/2015/doc/programming_FabISP.html

File

FabISPtraces.png

FabISPtraces.png

FabISPinterior.png

FabISPinterior.png

FabISP.png

FabISP.png

Material Used :

Copper cladmachineused :

Modella

Basic Electronics

Shopbot

Michael Mathews

Basics about electronic components

Basics about microcontrollers

Registers

Fuses (HIGH, LOW, EXTENDED) Tutorial: http://fabacademy.org/archives/2015/doc/fuses.html

Interrupts

ADC

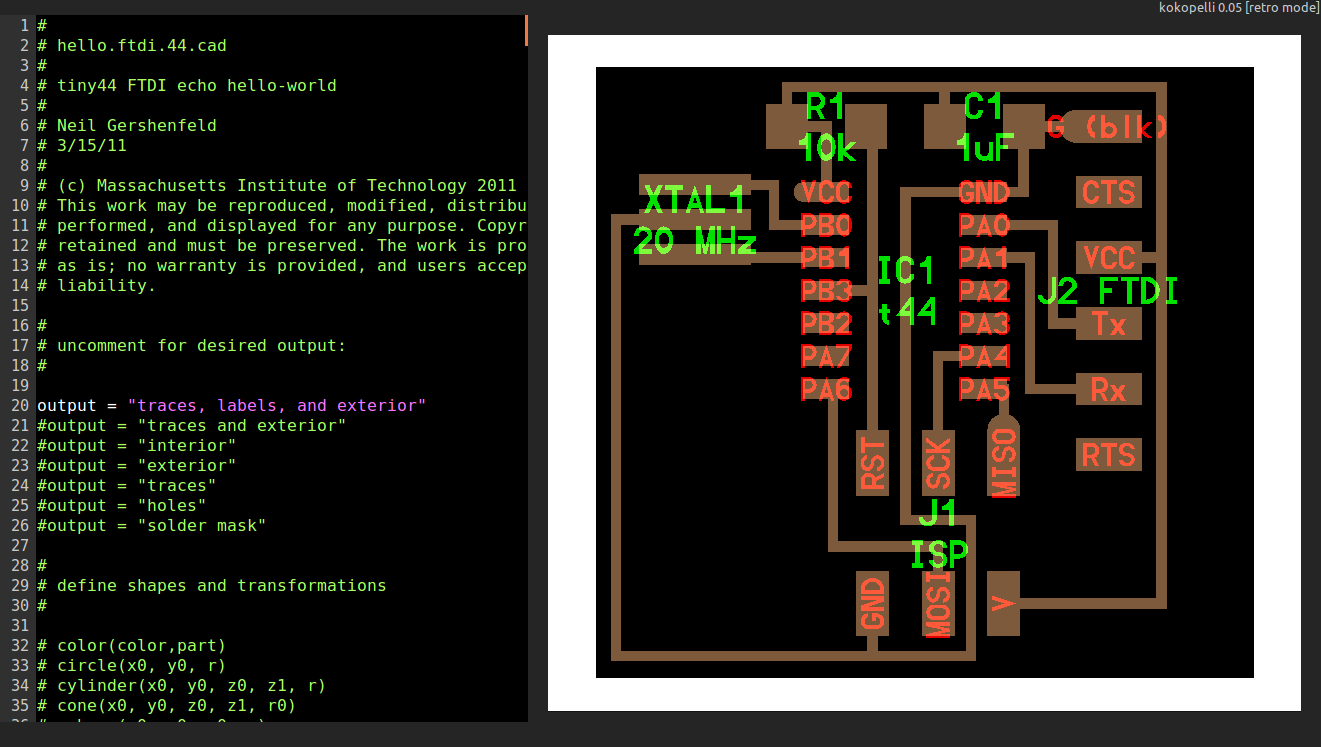

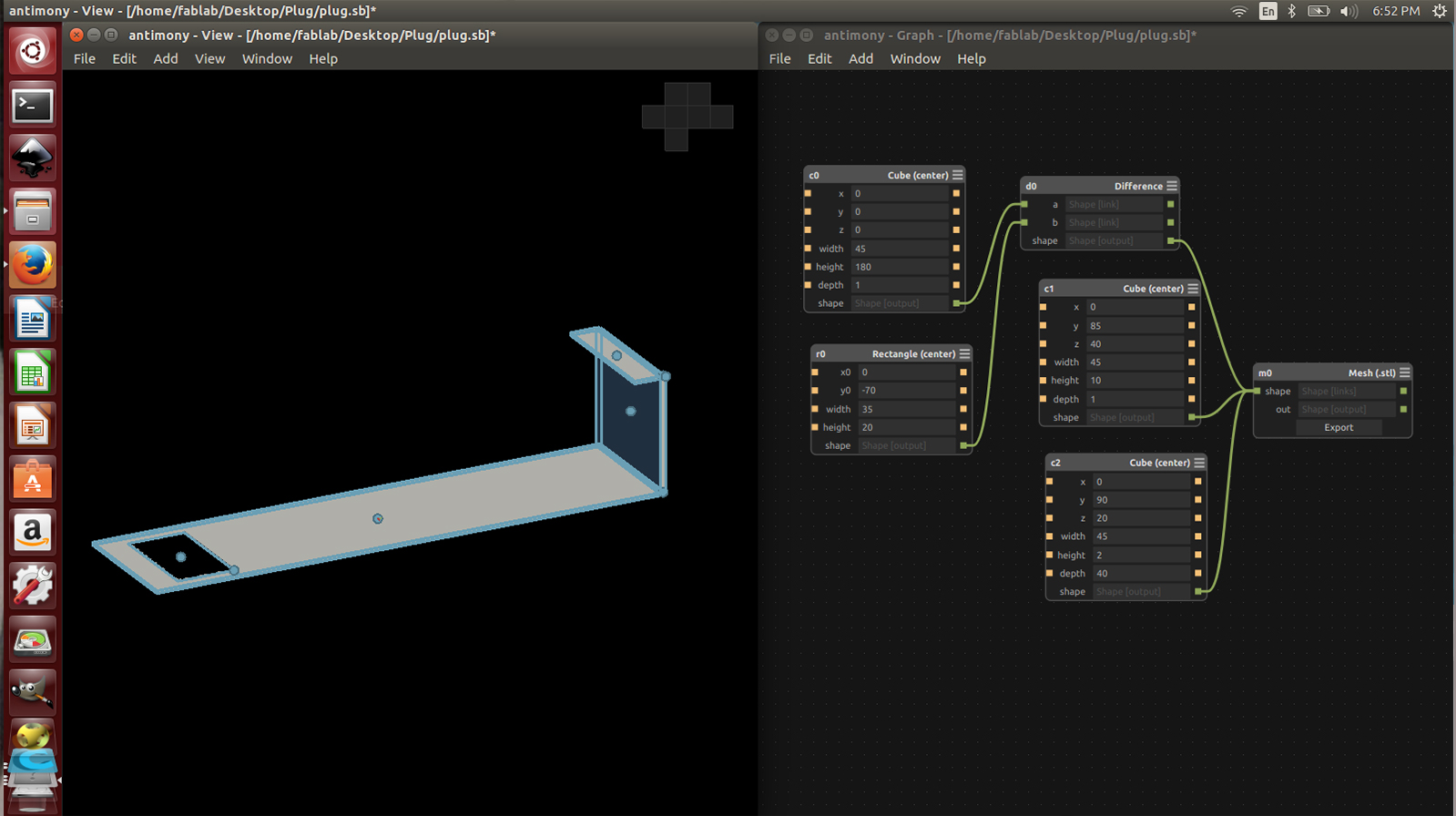

Modifying CAD Files with kokopelli

Crash course: http://fabacademy.org/archives/2013/students/sanchez.francisco/weekly-assignments/week-06/index.html Changing the output

Adding components

Adding traces

Advanced: Creating your own components

Advanced: Non rectangular cutouts

Assignment: Add an LED and a button to Hello World board

From line 5593 onwards where "#define board " - change the parameters like width of line, board width and length etc.

#

# define board

#

w = .016

width = 1

height = .93

mask = .004

x = 1

y = 1

z = -.005

d = .06

It is not recommend below for trace width(w) to be lesser than 0.012. Assign intelligent values for these parameter and let it remain default unless theres a problem.

Design

The following editions were committed in the file. this code is added under #define board and before #select ouput. The PCB had trouble with placingthe 6mm push button, hence we had to resize the board make it wide and reposition IC. Code:

# define board

#

w = .016

width = 1.2

height = .93

mask = .004

x = 1

y = 1

z = -.005

d = .06

....Uneditted code

.

.

# repositioned the IC. Every other element seems to #positioned relative to the ic.

pcb = wire(pcb,w, IC1.pad[13],

point(IC1.pad[13].x+.105,J2.pad[4].y,z),

J2.pad[4])

.

.

.

#adding led

LED1=LED_1206('Led') #usually the format is like component_size('name')

pcb= LED1.add(pcb,XTAL1.x,IC1.pad[5].y,z,180) #showing the led

R2=R_1206('R2\n1k') #adding resistor and naming it "R2 1k"

pcb= R2.add(pcb,LED1.pad[2].x,LED1.y-0.15,z,-90)

B1=button_6mm('B1') #adding push button

pcb=B1.add(pcb,LED1.x+0.2,J1.y+0.05,z)

pcb = wire(pcb,w, #adding traces

IC1.pad[5],

LED1.pad[1])

pcb = wire(pcb,w,

LED1.pad[2],

R2.pad[1])

pcb = wire(pcb,w,

J1.pad[6],

R2.pad[2]

)

pcb = wire(pcb,w,

IC1.pad[6],

B1.pad[4]

)

pcb = wire(pcb,w,

J1.pad[6],

B1.pad[3]

)

Exporting as .png

(make sure you name the file with the extension or else the export wont work and throw an exception)

Files

hello.ftdi.44.cad

hello.ftdi.44.cad

hello.ftdi.44.png

hello.ftdi.44.png

Programming

Arduino ide- most user-friendly, many tools, quick, easy

C - intermediate difficult, need to have more hardware knowledge, more efficient in code handling and storing, more freedom to program.

Assembly lowest level of programing, need to have through understanding of the hardware also, more difficult, highly efficient in code handling and occupies least storage, and allows most freedom to program.

Basics about programming

Add Author, date, description and license

Always comment your code

Init and loop parts

Digital output

Analog output (PWM)

Digital input

Analog input (ADC) 8 bit/10bit

Pull up down resistors (10k)

Multitasking? Polling

Debounce buttons

Programming. 3 paths depending on proficiency:

Beginners: Arduino IDE

Intermediates: C

Advanced: Assembly

Why C? https://www.youtube.com/watch?v=ERY7d7W-6nA&feature=youtu.be

Why Assembly? https://en.wikipedia.org/wiki/Apollo_Guidance_Computer

Assignment

Make LED blink

Turn ON/OFF LED

Serial communication (send something to computer, read something from computer)

Files

blink.ino

blink.ino

blink_serial.ino

blink_serial.ino

blink_switch.ino

blink_switch.ino  blink_keyboard.ino

blink_keyboard.ino

Video Conferencing

How to Use mcu.cba.mit.edu

How to acess Diffrent Channels

Steps for Completing a Fab Project

Installed Ekiga and Tested Communication

Line with 1Mbps Uplink at least. If only 1Mbps Uplink is avaliable then dedicated line recommended.

Software

Mac and Windows: Chrome Addon Jabber Call

Ubuntu: Ekiga or Linphone

Connections

Lab Connection: mcu.cba.mit.edu

Individual connection: mcuc.cba.mit.edu

Normally only lab connects to MCU. Individual only for special reasons: Travel, illness...

Important Rooms

1 Fab Labs

4 Class (protected by pin number) Pin shared at Fab Academy start

Booking a room (Specify timezone): https://docs.google.com/spreadsheets/d/1eZUNi7_2wsY3-YTyPQIBnljpAxztgQfcJgpNATWwn-w/edit#gid=0

Muting

Local mic mute. Check that always is muted except for talking

MCU mute. By default your are muted. Check that your microphone is locally muted and then to toggle MCU unmuted/muted dial *6

After talking remember to locally mute your mic again

Wednesday Class

Class starts at 9 AM Boston Time (EDT) Check your local time every week: http://www.thetimezoneconverter.com/

Lab Manager joins at 8:30 AM EDT for class preparation

Beware winter/summer time changes. Not the same all around the world

If connection does not work for some reason do not hammer the entire class mailing list. Check first with other people to see if it is a local or global problem.

Setting up the scene

World is watching and listening to you. Prepare a nice looking environment

Check Focus is correct, lighting is enough

Avoid bright backgrounds

Frame the entire class

Have a seat near the mic and camera for the person showcasing

Assignment: Check the time in Boston, Taipei and Barcelona and talk to them in the Fab Lab Room. Mute/Unmute in MCU. Prepare the lab for videoconferencing.